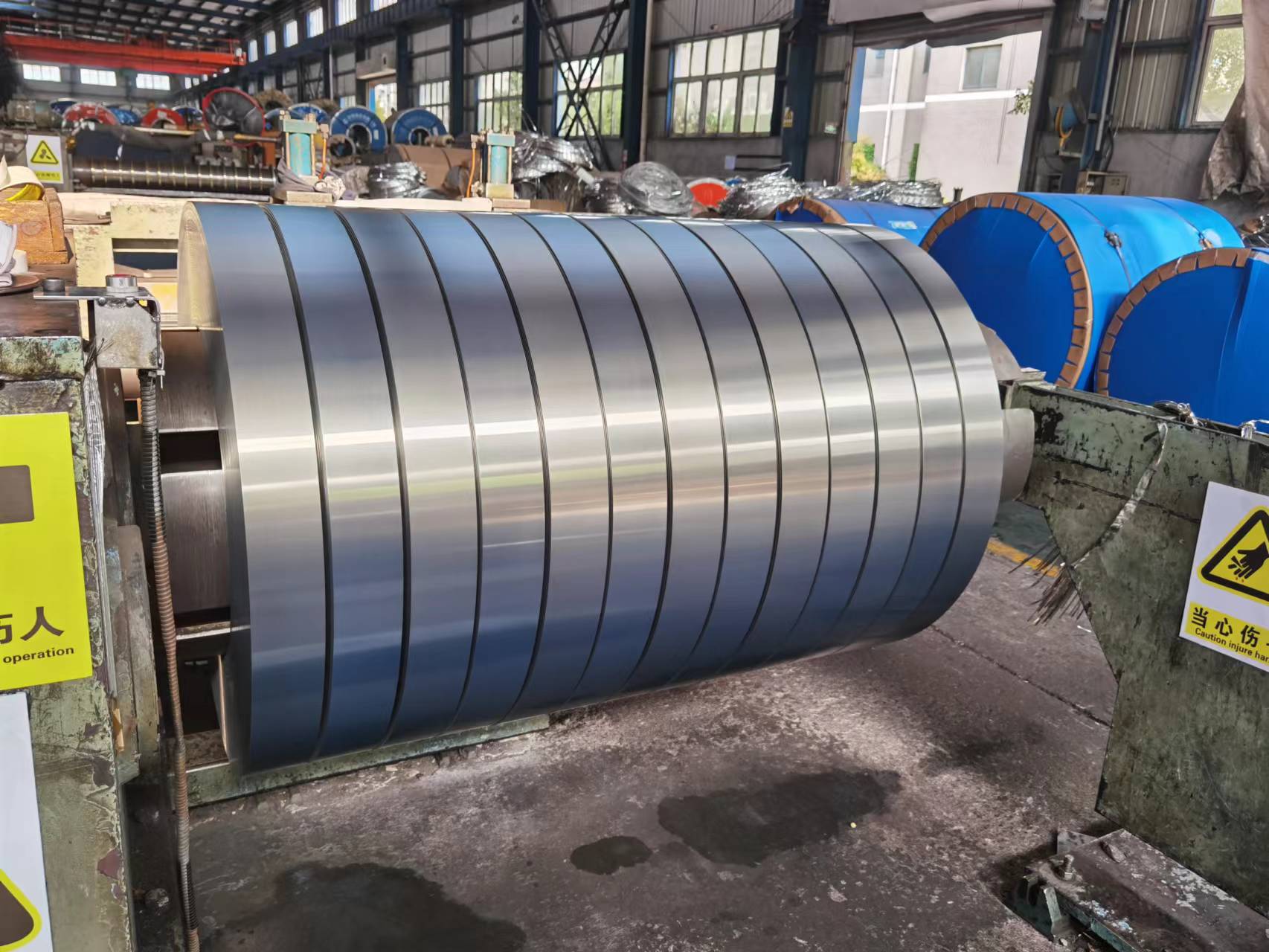

Thickness: 0.2-4.0mm

Width: 600-2000mm

Length(sheet): 1200-6000mm

Coil ID: 508/610mm

Material:SPCC,SPCD,SPCE/DC01.DC02.DC03/ST12,Q195.Etc

MOQ: 25Tons

Delivery time: 7-15days

Grade | A36, SS400, Q195, Q235A, Q215, Q345B, Q235B, Grade50, SPCC,SPCD,SPCE,st12,st13,st14,st15,st14-T |

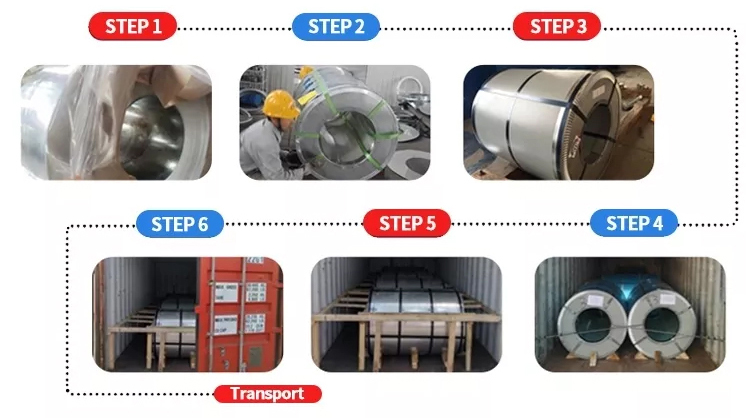

Process service | Slit cut, average into smaller coil and so on |

Standard | JIS/SUS/GB/DIN/ASTM/AISI/EN |

Technique | Cold Rolled |

Thickness | 0.2-4mm; Customized according to customer requirements |

Width | 1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm |

Lead Time | 7-15 working days after the receipt of 30% deposit |

Payment Terms | T/T, L/C or according to customer requirements |

Price Terms | FOB, EXW, CIF, CFR |

Packing | Bundled with strong steel strips or with waterproof packing materials |

1.The cold-rolled coil products are accurate in size, uniform in thickness, and the thickness difference of the coils generally does not exceed 0.01-0.03 mm or less, which can meet the requirements of high-precision tolerances.

2.It is possible to obtain extremely thin strips that cannot be produced by hot rolling (up to 0.001 mm or less).

3.The surface quality of cold-rolled products is superior, there are no defects such as pitting, hot-pressed iron oxide,

etc.,which are often found in hot-rolled coils, and coils of different surface roughness (glossy or hemp) can be produced

according to user requirements. Rough surface, etc., to facilitate the processing of the next process.

4.The cold rolled plate has a good mechanical properties and process properties (such as higher strength, lower yield limit, good deep drawability, etc.).

5.High-speed rolling and full-continuous rolling can be realized with high productivity.

Packing&Shipping